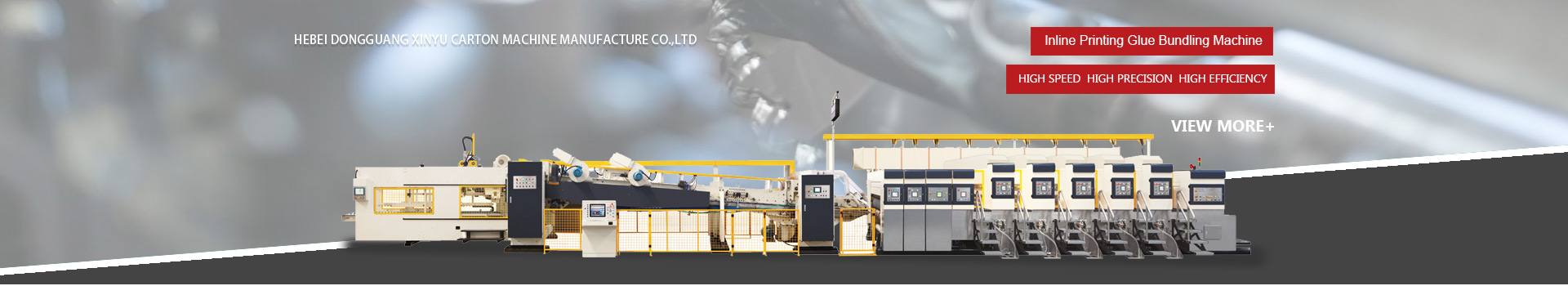

Feeding unit

Feeding part transfer cardboard to printing roller by 5 conveyor ,chain feeding with feeder operation and when operate must keep the same level ,right and left gauge ensure and control cardboard gradient ,the size of gauge is decided by the cardboard width .from printing center line to the ends bisection

Print unit

1.printing roller

(1)External diameter :405MM

(2)Steel tube surface grinding ,hard chrome plating

(3)Make the balance correction ,work steady

(4)Fixed roll version axis

(5)Loading and unloading printing roller ,pedal switch electric control is turning point

2.printing pressure roller

Steel tube surface grinding ,hard chrome plating

Make balance correction ,work steady

Printing pressure roller clearance dial manual adjustment ,adjustment range is 0-12mm

3.anilox roller

(1)External diameter is medium 176mm

(2)Steel tube surface grinding ,pressure Anilox ,hard chrome plating

(3)Make balance correction ,work steady

LPI is220,240 (depend on customer request ,the biggest LPI is 250 )

With feeding system pneumatic auto lift and down device (anilox lift to touch the printing roller when feeding ,anilox roller is up and separate from printing plate when stop feeding )

4.rubber roller

(1)External diameter is medium 176mm

(2)Steel tube surface packing resistance rubber and make the balance correction .Rubber is special grinding , the ink effect is good

5.phase adjust system

(1)Planet gear

(2)Printing part adopt LCD screen control and electrical digital 360°adjustment

Manual adjustment horizontal position ,adjustment distance is 14mm

6.ink circulation

(1)Pneumatic diaphragm pump ,ink supply steady and operation easy

(2)Excellent ink screen pack ,filtering impurities

(3)Plastic ink-making roller

Die cutting unit

1. Die cutting upper roller

(1) surface grinding, plating hard burger, move smoothly(Taiwan maxdura 9mm thick rubber resistance).

(2) has speed limit compensation device.

(3) rubber roller to move transversely 40 mm, prolong the service life of the rubber.

(4) automatic repair device, improve pads utilization rate, can repair the three to four times.

2.Die cutting down roller

(1) surface grinding, plating hard burger.

(2) equipped with lift roller, no cardboard, mould roller to be automatic drop, reduce wear rubber roller.

3. Phase adjust system

(1) the planet type gear structure.

(2) the tacit understanding phase PLC and LCD control and electric digital 360 ° adjustment. (operation, stop all can adjust)

4.slotting knife Four slotting knife attachment

5.Kebo servo motor drive

Slotter unit

1, With precreasing . and ensure the board is not crushed .

2, Pressure line package quality polyurethane wheels to ensure the board strength from destruction .

3, Electric axial movement synchronous interaction , as the whole pre-pressure roller , pressure wrie wheel , upper and lower slot cutter , steering wheel adjustment simultaneously .

4, Pressline shaft , slotted wheel made of high quality alloy steel , balancing the weight test , the surface after grinding hard chrome plating .

5, Selection of high quality alloy steel slotted knife . tooth bland with of 7 mm .

6, high quality of slotting knives.

7, Four screw