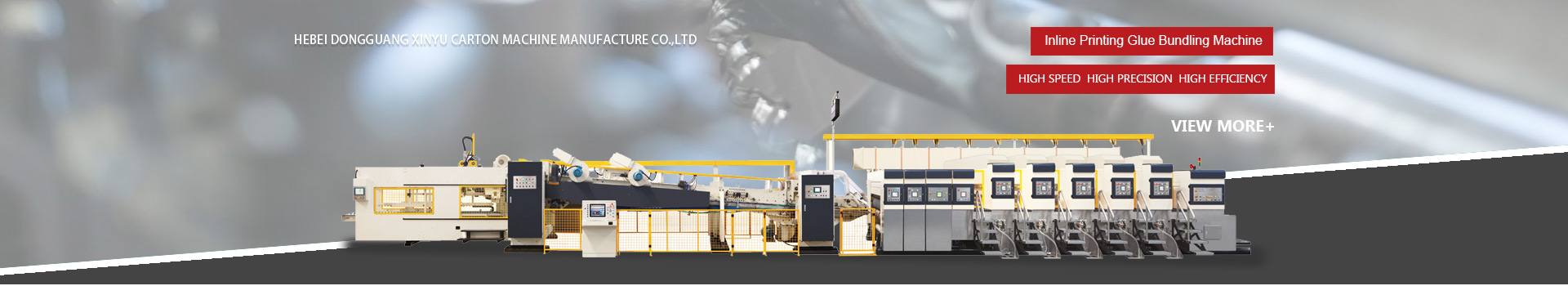

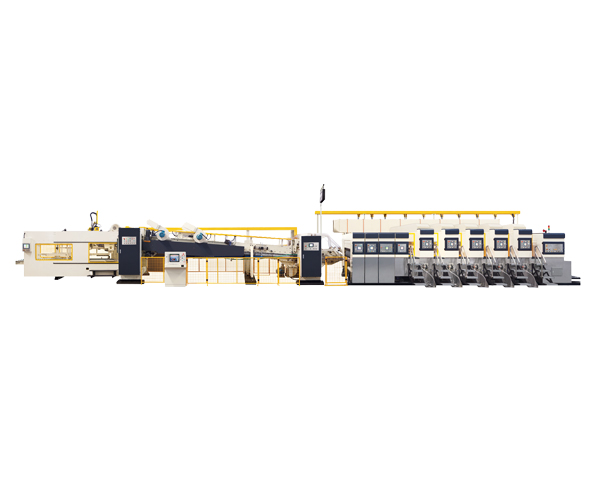

Specifications

● Adopt PLC touch screen control including the functions of indications of auto counting, speed, production, skip feeding and alarms;

● All transmission rollers are made of top quality steel processed through dynamic/static balance tests, chrome plating and polishing;

● Phase setting is done with Korean original digital meter to set current value to target value once precisely;

● China famous brand of transmission gears are adopted which are hardened and ground>60o Rockwell hardness;

● Main bearings from HRB

● Main electric components are purchased from the suppliers such as SCHNEIDER France and OMRON Japan;

● Spline free joint ring are employed to reduce center abrasion and remain precise registration for a long time;

● Auto zeroing and auto reset;

● Main motor start protection, main motor can not start when it is not locked to avoid maloperation;

● Every unit of overall machine can be released automatically or separately, electric shifting and pneumatic locking with acoustic alarm in traveling to secure operators safety. The auto brake is able to stop machine running;

● Emergent protection: emergency switch is installed inside every unit to stop unit running inside machine for more security;

● The clearances of pull rollers, impression cylinder, rubber cylinder and anilox cylinder are all auto pneumatically locked.

● Specially made 7.5kW high pressure centrifugal fan, suction auxiliary feeding paper, smooth transmission, to ensure the smooth surface of the thin surface and lower quality of the smooth transmission of the board, the effect is obvious. Ensure adequate a

Lead edge

● Automatic suction lead edge feeder equipped with a 7.5kw suction fan to feeding cardboard, the blowing rate is adjustable by the transducer according to the degree of crook of cardboard in order to transmit cardboard smoothly.

● Use 10 inch touch screen

● The main control panel is composed of control buttons and touch screen, which is very convenient and reliable.

●The machine is launched by pressing the start button with two hands, which ensure the operator's safety.

●The side plate is electrical adjusted automatically while the backstop is adjusted manually.

● Sheet cleaner is equipped to remove the contaminants on the cardboard which will improves the printing quality.

● The upper transmission roll is made of seamless steel tube, the surface is covered wear proof rubber, which is also good at avoiding crushing the cardboard.

● The lower transmission roll is made of seamless steel tube, with the treatment of grinding, embossing, and chrome plated.

● The transmission between the upper and lower transmission roll is driven by double slider coupling, which is good at reducing wear down and transmitting smoothly.

● The transmission shaft equipped with electromagnetic friction clutch, for avoiding damaging the motor in case of misoperation or overload.

● Automatic counter for recording the cardboard supply quantity to show the output.

● Can Save orders,the number can reach about 100+.It is easy to operate in next time.

Print unit

● All the rolls and shafts are made of high quality steel, with the treatment of dynamic balance correction, grinding and chrome plated.

● The printing phase position is and horizontal movement controlled automatically by touch screen with digital display, the phase position could be adjusted CW or CCW easily with 360 degree because of the equipping of PLC and planetary gearing mechanism.

● Equipped with ink quantity monitoring system, the machine will alarm when out of ink, and stop feeding cardboard.

● The printing plate is hanged by the hanging plate device, the printing roll is able to clockwise rotate and counter clockwise rotate which controlled by the foot switch, it's very convenient for installation and dismounting of printing plate.

● Manual gap adjustment via worm reducer with graduated dial indication such as gap between rubber roll and anilox roll, gap between anilox roll and printing roll etc.

● Equipped with electromagnetic clutch break system to fix the printing phase, when separate the printing unit for adjusting the printing phase, the break system will prevent the gear move, keep the original position.

● Phase clear memory and reset after printing plate cleaning.

● Steel anilox roll :215mm with the treatment of grinding, pressing overlapping curve and chrome plated.

● Also can ceramic roller and doctor blade ,the LPI can up to 800,depend on customer requirements,300-800LPI

● Printing roller diameter is 393mm,include the printing plate is 405 mm

Slotting unit(optional unit )

●All creasing and slotting parameter to be fed through computer (CNC)

●All knives and creasers to be revolved 360 degree and lateral movement for adjustment with micro switches

●Adjustable while the machine is running

●Depth adjustment with one to one

●All linked through yoke system for accurate alignment

●Four pairs of creasing removable collars acting on polyurethane surface

●Standard knives dimensions, micro-switch adjustment both on the unit and remote.

●Waste/ trim remove shall be included

●Box minimum and maximum size to be indicated

●Slotting Knives thickness to be 7mm

Die cutting unit

1. Die cutting upper roller

(1) diameter is 378 mm,include the plate is 398 mm, surface grinding, plating hard burger, move smoothly(Taiwan maxdura 9mm thick rubber resistance).

(2) has speed limit compensation device.

(3) rubber roller to move transversely 40 mm, prolong the service life of the rubber.

(4) automatic repair device, improve pads utilization rate, can repair the three to four times.

2.Die cutting down roller

(1)diameter is 360 mm, include the plate is 410mm surface grinding, plating hard burger.

(2) equipped with lift roller, no cardboard, die roller to be automatic drop, reduce wear rubber roller.

3. Phase adjust system

(1) the planet type gear structure.

(2) the tacit understanding phase PLC and LCD control and electric digital 360 ° adjustment. (operation, stop all can adjust)

4.slotting knife Four slotting knife attachment

5.Kebo servo motor drive can increase the accuracy ,and separate unit