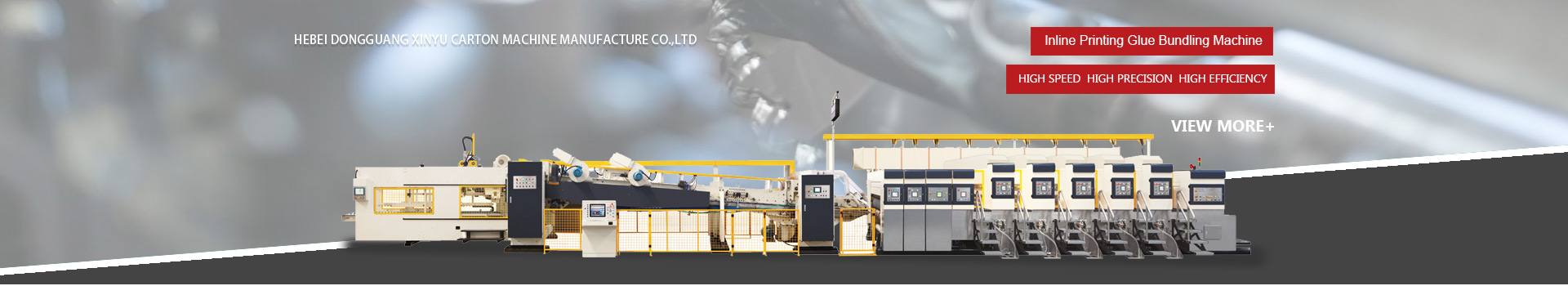

Features:

Imported double servo-motor, high precision.

Touching screen controlling system, easy operation.

SIMENS controlling system.

Backwards electrical clamp, stepless motor driving system, convenient to adjust the size.

All the electronics are from TAIWAN brands.

Bottom mould and the blades are imported from Japan brand.

The whole stitching wires are made of special iron steel, high precision finishing.

Taiwan air compressor.

Could make single stitching( / ), double stitching( // ), enhancing stitching( // / or / //), finishing in one time.

Different size changing time could be finished in one min, saving time.

Auto counter in Feeding system.

Conveying section has sensor device, auto delivering.

The collecting section can be programmed for pieces in pile, convenient for wrapping.

Auto-alarm for the stitching wire, when wire finished, will remind operator to re-fill.

Only two operators are needed for whole procedure.

| Max size(A+B)X 2 :3800mm | Min size(A+B)X2 :800mm |

| Max size (C+D+C):3000mm | Min size (C+D+C):250mm |

| Max D:2000mm | Min D:150mm |

| Max C:330mm | Min C:70mm |

| Max B:760mm | Min B:150mm |

| Max A:1140mm | Min A:250mm |

| Max E:40mm | Max paper pile height:900mm |

| Dimension :2800*1800*2000 | Weight :2ton |

| Speed :600 nail/min | No of nail:0-99 |